A brush with reality

Earlier this year Technical Surfaces, the UK's leading synthetic maintenance specialists, commissioned the undertaking of a report by Loughborough University at the Sports Technology Institute to assess the effect of brushing on the wear of synthetic sport carpet systems.

Earlier this year Technical Surfaces, the UK's leading synthetic maintenance specialists, commissioned the undertaking of a report by Loughborough University at the Sports Technology Institute to assess the effect of brushing on the wear of synthetic sport carpet systems.

The research was undertaken by Dr. Paul Fleming, to give factual back-up to what Technical Surfaces already knew through field work, that brushing, carried out in the correct frequency, and with the right machinery, will not detrimentally damage the carpet.

"We began sweeping our first pitch back in 1995," commented Jonathan Gunn, Technical Director at Technical Surfaces."This evidence was more to silence the critics within the industry than the pitch or facility owners who have always been more than happy with the work we do."

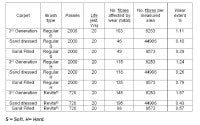

The preliminary meetings between Technical Surfaces and Dr. Fleming identified three brush types and three surface types for testing. The specifications for the test procedure (including rotation speed, brush head ground speed, depth of brush embedment into the surface under test, direction of rotation and brush size) were also agreed during the initial trials.

"The tests basically concentrated on three brushing techniques we use, frequent/regular soft brushing, frequent/regular harder brushing and more intensive annual or bi-annual Revite®. The reason we use two different types of brush on our frequent monthly/bi-monthly sweeping is dependent on surface type," said Jonathan.

"The tests basically concentrated on three brushing techniques we use, frequent/regular soft brushing, frequent/regular harder brushing and more intensive annual or bi-annual Revite®. The reason we use two different types of brush on our frequent monthly/bi-monthly sweeping is dependent on surface type," said Jonathan.

The cycles chosen give extreme examples of the use of Technical Surfaces' brushing techniques, as they wanted to show the worst case scenario and give a clear, unequivocal conclusion. Therefore, the cycles for the Regular brush replicated a weekly frequency (which is certainly possible), although in reality this type of brushing is generally carried out, at best, on a monthly basis to complement in-house drag brushing.

Therefore, the results for this section, which show 0,10, 50 weeks then 3, 5, 10 and 20 years can, in theory, be multiplied by 4 to give even more staggering results of 0, 40 weeks, then 4, 12, 40 and 80 years - still with minimal damage!

The following table shows the summary of testing carried out, with the specific details of the test set-up for each system and brush.

Notes: * 1 cycle = 2 passes of the brush in opposite directions of travel. The cycles are equated to 'life' as follows:

Regular brushes - done weekly at 2 passes (maximum) so 0, 10, 50, 150, 250, 500 and 1000 cycles is equated to 0, 10, 50 weeks and 3, 5, 10 & 20 years approximately.

Revite brush - done approximately annually (1 visit, 18 passes at each visit), so 0, 9, 18, 36, 72, 135 and 180 cycles is equated to 0, 1, 2, 4, 8, 15 & 20 years approximately.

When you consider that most facilities only expect their pitch to last for a ten year cycle, these figures show how the work that Technical Surfaces does has no impact on the shortening of a pitch's life. Indeed the oldest pitch that they maintain is now nearly twenty-five years old!

When you consider that most facilities only expect their pitch to last for a ten year cycle, these figures show how the work that Technical Surfaces does has no impact on the shortening of a pitch's life. Indeed the oldest pitch that they maintain is now nearly twenty-five years old!

S = Soft. H= Hard.

"The summary results clearly show a low level of wear that was observed to be caused by the brushing alone," says Dr. Fleming. "The life of 20 years was used to represent a period of time longer than most artificial pitches surfaces survive in practice. In reality, the effects of surface usage for playing the sport or training (total weekly hours at Loughborough University for example is around 50-65 per week on the soccer/rugby surfaces), and environmental effects are considered to be the main contributors to wear."

It is, therefore, considered that this study has shown that the contribution of maintenance brushing related wear is insignificant in comparison to the wear expected from the surface use and the exposure to the environment.

It is, therefore, considered that this study has shown that the contribution of maintenance brushing related wear is insignificant in comparison to the wear expected from the surface use and the exposure to the environment.

With the company maintaining some of the oldest synthetic surfaces in the country, it is easy to see that they have plenty of field experience. Now they have the data to show that their processes are an extremely effective way of prolonging the life of any synthetic surface. On-going testing and analysis of facilities' sites will continue. If you simply want to get the most out of your pitch or need your surface to pass stringent performance criteria, such as the FIFA 2 testing, the methods adopted by Technical Surfaces can now be recommended with even further confidence.

For more information, please contact Technical Surfaces on 08702 400700 or visit their new website www.technicalsurfaces.co.uk