Anyone for a Baileys?

Alan Bailey is heavily involved in the day-to-day running of the business and, in the topsoil industry, this literally means getting his hands dirty. During my visit he was busy painting his latest investment, a secondhand grading machine. Having stripped it down and serviced all moving parts Alan was giving it a final coat of paint. In keeping with many family run concerns, Alan has reinvested the profits back into the business.

It is very apparent that, if you're serious about manufacturing rootzones and topdressings, you need some pretty big pieces of kit. For example, the buckets on the loading shovels carry a seven tonne payload; the barrel on the drying plant cost a cool £250,000!

It is very apparent that, if you're serious about manufacturing rootzones and topdressings, you need some pretty big pieces of kit. For example, the buckets on the loading shovels carry a seven tonne payload; the barrel on the drying plant cost a cool £250,000!

Throw in a fifteen bay storage unit with the capacity to store 5,000 tonnes of topdressing in a clean, dry environment, a dozen power screeners, two bagging lines and a soil testing laboratory and you're getting close to the infrastructure needed to manufacture a product to a consistently high standard.

The Bailey's depot has the capacity to store thousands of tonnes of materials. As well as a perfect supply of raw material in the indigenous black fen Norfolk soil they also have a network of contacts able to supply other materials. Sand and topsoil are blended, graded and mixed as required by the end user. Alan's son Adrian, is Production Manager and oversees the movement of materials in the yard.

Keeping the materials free of contamination is imperative to the production and handling process. For example, at the quarry, the stockpiles of sand sit on a bed of the same material; this eliminates contamination from the quarry floor when loading. All vehicles are swept clean before loading to avoid contamination from the previous load.

Keeping the materials free of contamination is imperative to the production and handling process. For example, at the quarry, the stockpiles of sand sit on a bed of the same material; this eliminates contamination from the quarry floor when loading. All vehicles are swept clean before loading to avoid contamination from the previous load.

Ground contamination is eliminated at the production facility by loading and off-loading from a concrete pad. Once the rootzone or topdressing is produced, it is held in clean, dry holding bays, prior to loading for delivery. The shovel buckets are cleaned with every new mix and tyres are also kept clean so as not to contaminate the floor of the holding bays.

The company runs its own fleet of tipper lorries, allowing full control over deliveries, with drivers out on the road everyday. Topdressing is often delivered before 7.00am to allow easy access through clubhouse car parks, before they fill up with members' cars.

John Farrell MSc is the company's Technical Director and joined after graduating from the University of East Anglia in 1992. One of his first tasks was to set-up the original Soil Testing Laboratory.

John Farrell MSc is the company's Technical Director and joined after graduating from the University of East Anglia in 1992. One of his first tasks was to set-up the original Soil Testing Laboratory.

"We see soil analysis as an essential tool in testing whether a material is going to meet the required specification" said John. "Testing materials before their use in construction can help to ensure that quality materials are used and design specifications are met. Quality control testing during construction can provide assurance that consistent materials are being used, and provide reasonable expectations for consistent performance."

"Scientific research has identified the physical properties required of rootzone mixes used to build sports surfaces" John explains. "Analysing the physical characteristics of the existing rootzone, the particle size distribution, pH and organic matter levels, gives us a real picture of what that rootzone looks like. Armed with this information turfcare professionals can make informed decisions regarding their topdressing, maintenance and construction programmes."

In 2007 a brand new testing facility was opened. This is managed and run by Nigel Fahey B.Sc. who has been with the company for several years and is enthusiastic about the recent refurbishment of 'his' facilities. He highlights the manufacturing process as critical to the delivery of a consistent, topdressing or rootzone, and points out that the soil analysis laboratory is the foundation which underpins that process.

"Without a soil testing facility we would be working in the dark" said Nigel. "Analysis allows us to identify sands and soils suitable for the production of topdressings and rootzones. We are able to quality control the production process but, most importantly, we are able to supply our customers with up-to-date analysis."

"Without a soil testing facility we would be working in the dark" said Nigel. "Analysis allows us to identify sands and soils suitable for the production of topdressings and rootzones. We are able to quality control the production process but, most importantly, we are able to supply our customers with up-to-date analysis."

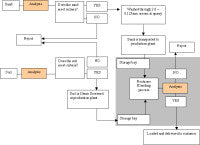

"The diagram below highlights where analysis can, typically, be used in the production of a rootzone. Having identified suitable sand, the production process begins by washing the sand. The washing process classifies the sand still further; washing it through a giant set of sieves isolates the desired material. Any material outside the range is waste. This is reduced by processing a sand which has a particle size distribution as close as possible to the desired specification."

"Sand is an abrasive material. Over time the sieves become worn and the sand grain size being delivered is increased; particle size distribution analysis at this point will monitor the effectiveness of the washing process. The results of laboratory analysis trigger appropriate actions, such as inspection, replacement, and modification, throughout the production process to ensure the correct material is produced."

The resulting specification sheets are provided as part of the laboratory testing support programme for customers. Each and every product sold and delivered has a detailed spec sheet showing textural classification, particle size distribution analysis and any other relevant information such as soil Ph, and nutrient status.

The resulting specification sheets are provided as part of the laboratory testing support programme for customers. Each and every product sold and delivered has a detailed spec sheet showing textural classification, particle size distribution analysis and any other relevant information such as soil Ph, and nutrient status.

"We see soil science as the most important tool available to anyone considering the construction of a sports surface" said Nigel "Without scientific analysis the suitability of materials is difficult to determine. Soil science can determine the appropriateness of raw materials, it can be used to monitor the rootzone manufacturing process, and can verify the suitability of a finished product. Whether constructing an 18-hole golf course or a village bowls green, the rootzone material should meet a defined criteria. The use of a material, which has not been tested, can lead to the failure of the surface."

John agrees; "Although initial installation costs may be higher, the long term costs, of rebuilding a failed green, or the lost revenue, because the rootzone surface is unplayable due to poor performance characteristics, more than justify the use of a quality controlled sports surface construction material."

Bailey's of Norfolk are members of the newly formed British Rootzone and Topdressing Manufacturers Association (BRTMA). The association was formed to ensure customers get a product that conforms to industry standards.

Bailey's of Norfolk are members of the newly formed British Rootzone and Topdressing Manufacturers Association (BRTMA). The association was formed to ensure customers get a product that conforms to industry standards.

Alan Bailey has a team around him that shares his passion for the products they produce. Over the years they have built up a portfolio of satisfied customers, including Norwich City Football Club, where they have developed products that suit their specific requirements at both the training ground and stadium. And, should there ever be a problem, Head Groundsman Gary Kemp can always bend the ear of one of his regular match day helpers, one John Farrell!