Aston Villa head groundsman has a light bulb moment!

One of the major advances has been the pitch construction. Most are now utilising either Desso, Fibrelastic or Fibresand, with undersoil heating and automated pop-up watering systems as the norm. The major benefit of having reinforced pitches is to allow better drainage capacity.

One of the major advances has been the pitch construction. Most are now utilising either Desso, Fibrelastic or Fibresand, with undersoil heating and automated pop-up watering systems as the norm. The major benefit of having reinforced pitches is to allow better drainage capacity.

However, there is a price to pay for having such a free draining, inert profile, as nutrients leach very quickly, so a robust feeding programme is required to keep the plant healthy. They also have to be watered more readily to keep them stable.

I met up with Jonathan Calderwood, the Head Groundsman at Villa Park, one of a number of Premiership groundsmen who are leading the way in pitch management to ensure the best possible playing surfaces are provided for their players, both at the stadium and training grounds.

Jonathan began his career in groundsmanship back home in Ireland, with a week's work experience at Glentoran Football Club, a team he had supported in his youth.

"I always wanted to work in football," says the 31-year-old. "After my stint at Glentoran, the club lost its head groundsman, so they asked me to step in."

Gaining his NVQ in horticulture from Greenmount Agricultural College, Antrim, he moved to Myerscough College, Preston, to study for an HND in turf science and sportsground management.

"During my time at Myerscough, I had the chance of a work placement at Wembley Stadium, and that was something I simply could not turn down." This led to Jonathan becoming assistant head groundsman during his three year stint at the famous old stadium.

"During my time at Myerscough, I had the chance of a work placement at Wembley Stadium, and that was something I simply could not turn down." This led to Jonathan becoming assistant head groundsman during his three year stint at the famous old stadium.

He worked at Wembley until it was demolished in 2001, and has many happy memories of the stadium. One of the highlights was that, along with other staff members, he played the very last game of football on the hallowed turf before it was ripped up and sold for charity. He even scored the last goal.

After a six month holiday, Jonathan returned to groundsmanship, becoming head groundsman at Molineux, taking over from Dave Saltman, who had left to pursue some odd new business venture called Pitchcare.com!

During his time at Wolves, he won the coveted title of First Division Groundsman of the Year 2002/2003, and continues to be mentioned in dispatches. At the time, he was employed by Sportsturf Maintenance, who had the contracts for several clubs, and this led to Jonathan overseeing work at two other clubs - Aston Villa and, for one year, Tranmere Rovers.

In 2006, American entrepreneur Randy Lerner, who already owned the Cleveland Browns American football team, bought Aston Villa, and asked Jonathan to take up a full time post at the club, to be responsible for transforming the pitch facilities at both the stadium and training ground at Bodymoor Heath.

In 2006, American entrepreneur Randy Lerner, who already owned the Cleveland Browns American football team, bought Aston Villa, and asked Jonathan to take up a full time post at the club, to be responsible for transforming the pitch facilities at both the stadium and training ground at Bodymoor Heath.

Lerner's multi-million pound investment in training facilities, as well as a new pitch for Villa Park, heralded a host of new playing surfaces.

Bodymoor Heath's reported £20 million revamp included new £5 million-plus floodlit facilities and three full-size first team practice pitches - one a replica of Villa Park's Desso surface, including its camber, undersoil heating and irrigation - two Fibresand pitches and a full size 3G synthetic pitch. The original training areas now accommodate academy teams on seven full size pitches laid on a 70/30 sand/soil substrate.

A huge fleet of maintenance machinery, equipment and vehicles, and a fourteen strong grounds support team, were also added.

In 2006, Jonathan was able to reconstruct the stadium pitch, replacing the old Desso system installed back in 1996, with a brand new, up-to-date Desso system. The original pitch was one of the first of this specification to be used in the UK, and the rootzone used was of very fine particle size, which, unfortunately, compacted very readily. "There wasn't anything wrong with the old pitch in terms of wear and tear," says Jonathan, "but the severe soil compaction meant that replacement was the only option. The new version uses a coarse, virtually pure, sand rootzone and required an intensive trace element package application every four weeks for the first two years to build up nutrient values in the inert rootzone material as supplied."

In 2006, Jonathan was able to reconstruct the stadium pitch, replacing the old Desso system installed back in 1996, with a brand new, up-to-date Desso system. The original pitch was one of the first of this specification to be used in the UK, and the rootzone used was of very fine particle size, which, unfortunately, compacted very readily. "There wasn't anything wrong with the old pitch in terms of wear and tear," says Jonathan, "but the severe soil compaction meant that replacement was the only option. The new version uses a coarse, virtually pure, sand rootzone and required an intensive trace element package application every four weeks for the first two years to build up nutrient values in the inert rootzone material as supplied."

Jonathan is a big fan of the Desso system, but is keen to stress that good maintenance practices are essential to get the best out it. "End of season renovation begins with stripping out all of the natural grass species. This generally requires approximately eight passes to avoid disturbing and damaging the precious Desso synthetic fibres, which are intentionally left in place. We bring in contractors to do this specialist work, as they have the specifically designed machinery. We don't want to use anything too brutal, or the fibre strands will be ripped out."

"The Desso pitch at Villa consists of over twenty million artificial grass fibres, which are injected to 20cm depth. This still only represents 3% of the total grass area, so that 97% of the turf will be natural species, but three times more durable than 100% grass."

"After the natural perennial ryegrass and old topdressing has been removed from the surface, the pitch is re-dressed with 80 tonnes of sand to match the rootzone. This is followed by vertidraining and dragbrushing to incorporate the sand into the newly created holes. An 18:22:5 pre-seed fertiliser is then applied, together with a calcium based pH correction formulation, to maintain levels at 6.5."

"After the natural perennial ryegrass and old topdressing has been removed from the surface, the pitch is re-dressed with 80 tonnes of sand to match the rootzone. This is followed by vertidraining and dragbrushing to incorporate the sand into the newly created holes. An 18:22:5 pre-seed fertiliser is then applied, together with a calcium based pH correction formulation, to maintain levels at 6.5."

The next process is overseeding with a 100% perennial ryegrass mix, using a dimple seeder sowing in three directions. Jonathan doesn't like to see the seed establishing in rows. "The ideal scenario would be to use a dimple seeder in conjunction with a disc seeder to get maximum even establishment," he says. "After eight days, we begin mowing at 35mm, and apply a granular 12:0:12 fertiliser, as nutrients leach quite readily in the predominantly sand rootzone."

"We've been using DLF Johnson's Premier seed mix for a number of years and are really happy with its performance. It  retains a good winter colour and recovers well. It stands up well to the hard wear of an intensive programme of fixture and training sessions."

retains a good winter colour and recovers well. It stands up well to the hard wear of an intensive programme of fixture and training sessions."

"We have perfected our own way of managing our playing surfaces. I'm no longer so paranoid about grass cover, and am more focused on playability - speed, trueness and traction. Yes, colour and presentation is still high on the agenda, but other criteria come first."

Lighting rigs, targeted feeding programmes that also include a number of other applications of products, such as growth retardants, bio stimulants, fungicides and trace elements, along with traditional cultural practices - brushing, aeration and mowing - help produce the quality of pitch the modern player requires.

"There is no one thing that makes a good pitch," suggests Jonathan. "It is about managing all the components and resources effectively, and not being afraid to try new methods of maintenance and application of products. That's where the training ground comes in handy, as any new methods can be trialed there first."

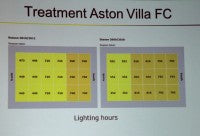

The club have invested in Stadium Grow Lighting (SGL) costing around £350,000, which allows good turf growth conditions  and makes overseeding possible in the winter months. The system is used from mid October until March or April, depending on conditions.

and makes overseeding possible in the winter months. The system is used from mid October until March or April, depending on conditions.

"We have six SGL MU360 lighting rigs, along with smaller rigs for the goalmouths, which allows us to cover one third of the pitch at any one time," explains Jonathan. "They are left on for two days, before moving to the next position, therefore the grass gets a four day break before it gets the next dose of light. We need to be careful not to overdo it, it's all about getting the balance right. If they are overused, the plant can become overworked and weakens the sward."

Jonathan logs on to the SGL website to monitor the amount of light other clubs are using. "I'm often surprised to find that they can be utilising them three times the amount that we do at Villa, but understand that no two stadiums are the same in terms of shade and light and, along with local weather conditions, the groundsmen will have done their homework to suit the needs of their own pitch."

"One of the major factors that has to be considered with these lighting rigs is storage. We have to store ours in the car park,  and the only access onto the pitch is by taking them down the road, which takes up a lot of time. This, in turn, can reduce the time available before and after matches."

and the only access onto the pitch is by taking them down the road, which takes up a lot of time. This, in turn, can reduce the time available before and after matches."

"The lights, used in conjunction with all the other practices, have certainly helped produce a better sward," explains Jonathan. "Using them also means that, even in winter, the grass plant needs feeding just as regularly, so we've formulated a regime that provides the right amount of essential nutrients to keep the grass performing throughout the year. Regular soil analysis tests are taken to monitor nutrient status, and appropriate products are applied. These are centred around a slow release base feed, topped up with additional granular and foliar feeds."

"During the main growing season, something like a 12:0:12 is applied every two to three weeks, depending on growth levels, plus further doses of 19:5:18 every eight weeks. In addition, a bio-stimulant liquid is sprayed onto the pitch, at efour-week intervals. To balance fertility, we use a STEP trace element package every three months."

"During the main growing season, something like a 12:0:12 is applied every two to three weeks, depending on growth levels, plus further doses of 19:5:18 every eight weeks. In addition, a bio-stimulant liquid is sprayed onto the pitch, at efour-week intervals. To balance fertility, we use a STEP trace element package every three months."

The mowing height is gradually lowered to 21mm for the start of the season, and the fertiliser programme changes, in the autumn, to applications of conventional 7:0:14 every 14-21 days, and a 15:0:28 slow release formulation every eight weeks.

The only disease problem encountered has been Leaf Spot, which is treated with a fungicides as soon as it appears.

The club has invested close to one million pounds on equipment and the lighting rigs, with most of the machinery based at the training ground. "Machinery needs at the stadium are minimum," says Jonathan. "The modern thinking is to keep heavy machinery off the pitch, and all the work is now done with pedestrian machinery. Obviously, we keep things like linemarking machines, pedestrian sprayers and spreaders at the ground, along with a Toro Procore aerator. The only time any large equipment goes on to the stadium pitch is during renovations."

"We use Honda pedestrian rear roller rotaries to clean and mow the pitch, and only use the larger cylinder mowers for final presentation. We also use the cassettes for verticutting and brushing."

"We use Honda pedestrian rear roller rotaries to clean and mow the pitch, and only use the larger cylinder mowers for final presentation. We also use the cassettes for verticutting and brushing."

"Due to the large area of playing surfaces at the training ground, we use a mixture of pedestrian and triple mowers, along with tractor mounted equipment. Presentation remains important."

The availability of new scientific testing equipment is also coming to the aid of groundsmen, giving them the opportunity to record relevant statistical information about their pitches.

"I use a Clegg Hammer, once a week, to measure the hardness of the pitches," states Jonathan. "I take a number of repetitive readings to get an average measure of hardness. Anything over 90 gravities I feel is too hard. I like to keep it between 75-85 gravities. I control the hardness by the timing of aeration with the Procore. I also use a moisture probe to record soil moisture levels. Desso stability and firmness is determined by the moisture content. In the past, this was gauged by how it felt when being walked on, what it looked like and condition of the sward. Now, by taking a reading, I know exactly what moisture levels I am working with."

"Our pop-up irrigation system is invaluable. Being able to apply the correct amount of water accurately and quickly is a must when managing modern sand-based pitches. We apply about 5mm of water when needed to keep the pitch adequately watered. Like most clubs, we also water just prior to kick off."

"Our pop-up irrigation system is invaluable. Being able to apply the correct amount of water accurately and quickly is a must when managing modern sand-based pitches. We apply about 5mm of water when needed to keep the pitch adequately watered. Like most clubs, we also water just prior to kick off."

The traction of the sward and ball bounce is measured at various times during the season. "All this measurement helps me to have a better understanding of how the pitch is performing and, along with rain and temperature gauges, and our weather station, have become an integral part of our armoury."

"I attend all of Villa's away games, and try to make a point of meeting up with the groundsmen on the pitch. I find it very useful to see how my peers are operating but, equally important, I spend time catching up with the latest gossip!"

When it comes to maintaining a professional football pitch, the intensity and attention to detail has certainly changed in the last thirty years, whereas the passion, loyalty and commitment of the groundsmen hasn't.

Improved working conditions, state-of-the-art machinery, and new products and services have all contributed to help make Jonathan, and his fellow professionals at Premiership clubs, considered to be amongst the best groundsmen in the world. Their working practices put our industry firmly in the spotlight, week in week out.