Looking after a cylinder mower

Looking after bowling green and cricket pitch mowers is basic, but is the key to smooth running and trouble free mowing.

Most recent machines will have Kubota, Honda or Briggs and Stratton engines. It is important, for the life of the engine, to ensure that oil changes are carried out regularly. In addition, the oil level should be checked each time the mower is used.

Dirty air filters will reduce the life of an engine and will make it run rich. Therefore, appropriate air filter cleaning or filter replacement is important. Oil changes should be carried out every fifty hours.

On older Kubota and Briggs and Stratton engines use 30 grade oil. On later overhead valve engines use 10-40 grade oils. Air filters should be cleaned after 25 hours use and more often in dusty conditions. If the engine is troublesome to start, or will not start at all, it is usually one of three things - fuel,spark or compression.

The first thing to check is that there is petrol in the fuel tank and that it is being fed to the carburettor. Also, check that the choke is going to the full 'on' position and the primer, if fitted, is in working order. Also rememberthat if the main jet in thecarburettor is blocked the engine will not start. Remove the jet and blow clean. Next, check for a spark at the plug. To do this remove the plug from the engine, fit the plug to the lead and place on to the engine cowl, with a small gap between the lead and cowl. Pull the engine over with the recoil starter and look for a spark. If there is no spark fit a new spark plug and try again.

On older engines there will be a high tension coil, points and condenser which will require removal of the flywheel. On modern engines, with pointless ignition systems, there will be an HT coil on the outside of the flywheel, which is a lot easier to check. If the coil is faulty it will require replacement.

For loss of compression, look for incorrect valve clearances or burnt out valves, blown head gasket or broken connecting rod in the engine. This is a bit extreme and is the result of running with little or no engine oil in the sump.

Keep drive chains clean of dirt, adjusted and oiled. When adjusting the cutting cylinder it is a good idea to check the drive chain for adjustment.P utting the cutting cylinder on to cut will increase chain tension on certain mowers. Make sure that the drive chain is free of dirt.

Check front and rear rollers for wear in bearings and worn shaft. If you are trying to cut grass at 4.5mm, and have badly worn roller bearings, this will affect the qualityof the cut. Also remember to grease rollers that have grease nipples. It is probably best to use engine oil in the grease gun as this will penetrate better than grease.

If the rear roller halves will not spin on the roller shaft this will cause difficulty in keeping the mower in a straight line and also make it difficult to turn.In severe cases it will be necessary to remove the roller soit can be stripped for cleaning and repair.

On rollers without grease nipples the only way to lubricate is to remove the roller and to strip, clean and oil.

The next thing to look ati s how to adjust the cutting cylinder to the bottom blade. This is best done with paper. Junk mail is good for this (probably the only thing it is good for).

Adjust the cylinder so that it cuts the paper all the way along the blade. Then back off adjustment so that it creases the paper.

|

|

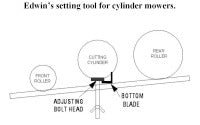

Probably the most important thing with a cylinder mower is how to adjust the height of cut precisely. I find it best to use a setting bar. This is used between the front roller, bottom blade and rear roller. The setting bar is usually about 12mm square and 4.5cm in length, with an adjustable screw and wing nut, to set the required size.

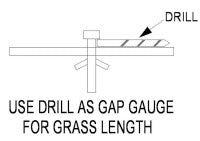

The way I do this is to use a drill. All drills have the size marked on the shank and are available in 0.1mm increments. I find 0.5 mm increments to be most useful.

Another possibility is to use Allen(hexagon) keys which are also size marked. Lay the drill on the bar, turn the adjusting screw in, trapping the drill. Lock up the wing nut. The bar is now set for use at the required size. Free off the front roller adjusting bolts. Place the setting bar underthe rear roller, hook the setting bar screw head on top of the bottom blade.

At the end of the season, with all the renovation work completed, you will probably all go off and play indoor bowls. Spare a thought for the equipment.

Put the mower away in a clean condition. Petrol can go stale over winter so drain out the fuel tank or, alternatively, fill the tank up and run the engine every four to six weeks. It is a good idea to leave the engine on compression. To do this pull the recoil rope and turn the engine until compression is felt.

This will leave both valves closed and seal the upper cylinder from the upper atmosphere.

Single cylinder engines will always stop with the exhaust valve open. The exhaust valve will be dry of oil and could seize up over winter.

Over winter the equipment shed can be a cold damp place. I recommend raising the mower off the floor by a couple of inches to allow air to circulate under the mower and stop the blades rusting at the bottom. A good spray of WD40 will also help.

It is important to send your mower off to your local service dealer for winter love and care. Don't leave this until March as he will be on his third nervous breakdown by then!

In summary, keep the mower clean, bearings greased or oiled, blades adjusted, and regularly check and change the oil, and all should be well.

Happy mowing.