Martin Lishman Ltd – a 40 year story of spraying innovation

Founded by Martin Lishman in 1975, the company has shown itself to be adept at spotting market trends and identifying how to respond to customer needs. It is still a family-run company, with Martin's son Gavin Lishman supported in the running of the business by his wife Carol along with the backing of a young and enthusiastic team of engineers and technicians. Their latest product is the Micro-Spray self-propelled pedestrian sprayer, but the origins of their involvement in spraying equipment goes back to Martin's early recognition of the demand for safer and cleaner ways to handle and apply pesticides.

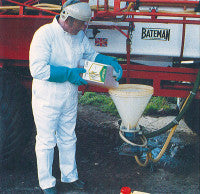

In the early 1980s, agro-chemical users were suffering the ill-effects of handling issues, especially when filling a sprayer. Environmentalists were none too happy either when neat chemical spillages and overflowing spray tanks started to cause measurable effects in water supplies.

In the days before sprayers were fitted as standard with chemical induction hoppers and transfer equipment, Martin Lishman introduced the Turbi-Filler chemical induction hopper. As one of the first of its type, this was retro-fitted to contractor fleets across the UK and to newly manufactured sprayers.

Being able to handle efficiently and quickly all types of chemicals, including powders, granules and sachets were important aspects of the Turbi-Filler. However, the potential exposure of the operator to neat chemical and the need to remove residues from empty containers were still major issues. The company addressed these with the very successful introduction of the CTR (Chemical Transfer Rinse), for which the company was awarded an RASE Silver Medal in 1994 for its contribution to spraying safety - a proud moment in its history.

Increasing spraying safety and avoiding the unnecessary application of chemicals in environmentally sensitive situations has been the focus of developments of the Martin Lishman spraying range over the past twenty years. They were the first to fit a separate 70 litre tank to a main sprayer to allow less hazardous chemicals to be applied near to watercourses and on conservation headlands. The Headland Control sprayer pre-dated the arrival of ATV quad bikes and UTV trucks so, when these versatile vehicles did appear, the scope for small sprayers as attachments grew exponentially and was a green light for the company to develop its own range of amenity sprayers.

Inevitably, in what became a mass market for small sprayers, cheap imports initially dominated and quality varied enormously. But the British-made Martin Lishman range, manufactured at their factory in Bourne, Lincolnshire, has stayed true to the company's principles of practical, innovative and cost-effective sprayers built to survive the rigours of all types of spraying.

"Our beginnings in agricultural spraying mean that we understand the demands that can be placed on sprayers in heavy use, but equally we recognise the need for an element of sophistication that top groundsmen are looking for - so we always aim for our range to reflect these principles," says Gavin Lishman.

From the early beginnings of the Mini-Spray 70 litre ATV-mounted sprayers, suited to small spraying jobs, demand grew as the available carrying vehicles developed and the range now includes trailed, tractor-mounted and demountable sprayers with capacities up to 600 litres and boom sizes up to 8 metres. The versatility of the range of Martin Lishman Mini-Spray and Midi-Spray machines allows sprayer operators and groundsmen working with most sports pitch sizes and facilities such as leisure centres, golf clubs and bowling greens to find a sprayer specification to suit their needs.

On a slightly smaller scale, Matt Edmonds, director of his own grounds and estate maintenance company, found that his 125 litre 12 volt Tractor-mounted Mini-Spray speeded up his work, when compared to using knapsack sprayers, and significantly reduced the physical toll on his operatives.

The latest addition to the range started life as an inter-row Christmas tree sprayer but, as with the Micro-Spray, has been re-specified and upgraded to a state-of-the-art self-propelled pedestrian sprayer ideally suited to football pitch maintenance requirements at clubs such as Leicester City and Forrest Green Rovers.

The Martin Lishman development team, headed by Production Director Lee Clarke, with input from engineering and electronic technicians Justin Stafford and Darren Overland and comprehensive testing by sprayer technical sales engineer Matt Handley, has brought a new concept in spraying versatility to the groundsman's armoury.

Combining control and power with responsive easy handling, the Micro-Spray has a 120 litre tank with a 2.5m or 3.5m folding boom that will suit the majority of spraying situations. Teamed with smooth tyres and a single front steering wheel, this ensures a low ground pressure footprint to keep tyre marks on turf as minimal as possible. Spray application rates, operating speed and the pump pressure can be accurately and quickly controlled by the operator. A specially designed ergonomic steering handle provides precise fingertip control and the propulsion system is designed to meet the latest machinery directives, making the sprayer suitable for use by local authorities and in public places.

The focus by Martin Lishman on sprayers for fine turf use has opened up another aspect to the business - one which stays true to the company's principles of encouraging environmental consideration in spraying and to Gavin Lishman's scientific training in ecology. "Compost tea is becomingly increasingly used in many aspects of amenity work," says Gavin. "The realisation that healthy soil biology is the route to healthy grass is informing the thinking of many groundsmen."

Compost tea is an aerated extract from high quality compost of beneficial micro-organisms that can be sprayed onto turf. As well as being 100% safe and natural, which allows it be used in sensitive public areas, users experience less turf disease, use less fertiliser and chemicals, use less water in irrigation and see an increase in rootzone depth.

Remediation of heavily used pitches, improving soil structure, eliminating unwanted species and maintaining pitches in top-level condition are just some of the reasons why headlining football clubs such as Real Madrid and schools with a strong sporting tradition, such as Oakham School, have invested in the range of Growing Solutions Compost Tea Systems. An added advantage is that compost tea is an ideal candidate for application using the Micro-Spray.

As if completing a full circle, sprayer safety has returned to the front-line offering from Martin Lishman. Timed to help sprayer operators meet the needs of the latest changes in chemical use regulations, in 2015 the company was appointed as an accredited NSTS sprayer testing centre. With three members of the sprayer production team, Lee Clarke, Justin Stafford and Matt Handley, fully qualified in all aspects of spraying methods and technology, all Martin Lishman amenity sprayers sold are specified to the latest safety standards. Customers have the option to buy their sprayer already NSTS certified or to retrospectively have their amenity sprayers fully checked and serviced and then certified.

Living up to the company's motto Meeting Change with Innovation, Martin Lishman has come a long way in its forty years of existence. With increased restrictions on chemical application having a major effect on the amenity industry, the focus on spraying safety and using replacement technologies such as compost tea place the company in an ideal position to serve the amenity industry for many years to come.