On the night shift ...

"The challenges seem to be ever increasing, season after season. There's always something new to bother us"

"The challenges seem to be ever increasing, season after season. There's always something new to bother us"

I received a phone call from Dan Duffy, the Head Groundsman at the Liberty Stadium, inviting me to attend Swansea City's final match of the season against Sheffield United, and to see, first hand, how the groundcare team go about preparing for match days. My previous visit was back in 2005, to report on the development and construction of the then brand new stadium, home to both Swansea City FC and the Ospreys rugby team.

Some six years later, Dan is still in charge of the pitch, and has also been nationally recognised for his hard work and dedication in producing one of the best playing surfaces in the country - Championship Groundsman of the Year 2008/09, Professional Groundsman of the Year 2008/09, Sportsturf Management Team of the Year 2009 and a finalist in the Groundsman's Groundsman of the Year 2010.

Over the years, he has built up a great relationship with fellow professional groundsmen, particularly Dean Gilasbey who, at one point, was his assistant at the Liberty Stadium, before moving on to take up the post of Head Groundsman at the brand new Llanelli Scarlets Stadium.

He has always been keen to pass on his knowledge and expertise to all the staff that have helped him, however, in typical Australian fashion, he does not suffer fools gladly and expects very high standards of workmanship.

The pitch at the Liberty is a Desso construction. Drainage consists of a primary grid system with 110mm diameter pipes set at six metre centres, overlaid with a  10mm gravel carpet, topped with a blinding layer of 6mm gravel. Over 5,000 tonnes of laboratory tested materials were laid to construct the pitch, consisting of a fully engineered gravel raft with a 90/10 on-site prepared sand and soil profile for the upper rootzone before being sewn with the Desso Grassmaster fibres.

10mm gravel carpet, topped with a blinding layer of 6mm gravel. Over 5,000 tonnes of laboratory tested materials were laid to construct the pitch, consisting of a fully engineered gravel raft with a 90/10 on-site prepared sand and soil profile for the upper rootzone before being sewn with the Desso Grassmaster fibres.

The pitch also has undersoil heating to help ensure it remains playable during periods of heavy frost and, like many clubs, it became a godsend during the bleak winter weather in December/ January, ensuring no games were lost.

In times of frost, Dan will drain down the irrigation as a precautionary measure, to ensure he does not lose the use of the system. The combination of using a lighting rig and undersoil heating can dry out the pitch significantly, so it is essential to have water available.

"The challenges seem to be ever increasing, season after season. There's always something new to bother us. "No two seasons are ever the same; the micro climate in the stadium presents its own set of challenges, along with the changing weather fronts." Swansea is reckoned to be one of the wettest cities in the UK, with an average rainfall of over 1,000mm.

"Temperature fluctuations are also a challenge; the pitch can become quite shaded in the winter months with temperature difference as much as 7°C from inside air  temperature to that outside. We acquired one set of lighting rigs that we use on areas of the pitch that are most prone to the elements, and high wear areas between the football and rugby. They are rotated around these three areas; forty eight hours in each area. The rigs are only used in these three high wear areas covering only 16% of the pitch. If we had access to more lights, we could achieve more."

temperature to that outside. We acquired one set of lighting rigs that we use on areas of the pitch that are most prone to the elements, and high wear areas between the football and rugby. They are rotated around these three areas; forty eight hours in each area. The rigs are only used in these three high wear areas covering only 16% of the pitch. If we had access to more lights, we could achieve more."

"The biggest wear comes from the rugby games, particularly around the scrummage, ruck, mauling and line out areas. It is common for the referee to re-set a scrummage several times over the same spot - over 800 kilos of muscle pushing down on the same piece of turf! You can also bank on this happening a lot around the centre spot and strategic scrum five areas."

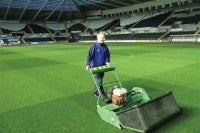

On arriving at the stadium on the Friday (6th May), a day before the match, I was met by Dan and introduced to two of his staff, who were busy mowing the pitch, east to west, using their Dennis G860s.

Dan's assistant is Dan Kirton, who came to the club last November, after returning from a sabbatical travelling around the world. He is very experienced in pitch management, having previously worked for six years at Chelsea's Cobham training ground.

Ben Arthure is employed two days a week. He is a relative latecomer to the industry, having previously worked in the steel industry upper management for thirty one years, retiring in 2009. He retrained in land based NPTC courses in tractor driving and machin ery operations, safe operation of a chainsaw and the PA1, 2 and 6 spraying certificates. He also has two NVQ level 3s in Operations Management and has just completed Sports Turf and Amenity Horticulture.

ery operations, safe operation of a chainsaw and the PA1, 2 and 6 spraying certificates. He also has two NVQ level 3s in Operations Management and has just completed Sports Turf and Amenity Horticulture.

He started working at the Liberty Stadium on a part time basis two years ago, helping with mowing, along with other tasks such as aerating, marking and fertilising the pitch. He also helps look after the machinery. He says he learned so much in the time he has been there, stating that Dan "always explains his decisions, so you really feel part of the decision making process during day to day operations at the stadium."

Ben is really enjoying his new outdoor life and has vowed never to work inside again. When not working at the stadium, He is actively volunteering his services at the Swansea Civil Service Cricket Club.

Whilst on the subject of staff, Dan has also trained up another member of the team, Anthony Harry who, for the last five years, has come in to help out on match days. Anthony is employed as a groundsman at Pencoed College looking after several winter games pitches. Here, he has attained various certificates and, was a finalist in the Young Groundsman of the Year.

Dan's working hours are legendary at the club - the amount of hours he does is staggering - eighteen hour days can be the norm when preparing and repairing the pitch for matches. So much so that he has become quite nocturnal, often starting in the wee small hours of the morning. "After Dean moved on to the new Scarlets stadium in May 2008, I basically had no full time, experienced assistant or staff until Dan started in September 2010. So I had to approach the job as a one man band, particularly on match days. I coudn't afford to lose time to any match day nigggles, and I got into the habit of allowing for more hours, just in case. Not taking anything away from my staff, who are hard working, totally dedicated and great guys. We always have a great laugh in each others company, that's why we all enjoy it so much."

And woe betide anybody who goes on the pitch without first asking! Dan likes to keep as much activity off the pitch as possible.

With both Swansea City and the Ospreys utilising the facilities, a busy match schedule is inevitable; this year, to date, Dan and his staff have hosted over forty-two games and numerous training sessions. "Although our game numbers are down this season, we had an incredible eighteen weeks from mid November through to mid  March - twenty-two games in total - some back to back - plus six rugby training sessions and more kicking sessions. It took its toll on us! Dan described it as intense, I say relentless! But, whether this is good or bad, we did have a tired looking pitch for the South Wales derby against Cardiff in early February which, to me, was a shame. The guys worked tirelessly and we all pulled together, which proves to me that this is the best groundstaff team in the country. I love these guys!"

March - twenty-two games in total - some back to back - plus six rugby training sessions and more kicking sessions. It took its toll on us! Dan described it as intense, I say relentless! But, whether this is good or bad, we did have a tired looking pitch for the South Wales derby against Cardiff in early February which, to me, was a shame. The guys worked tirelessly and we all pulled together, which proves to me that this is the best groundstaff team in the country. I love these guys!"

During the course of the season, they also get a number of back to back games; football on Saturday and rugby on Sunday, so pitch changeovers have to be quick. Football posts are taken down and rugby posts erected as soon as the football match is finished. The pitch is divoted, cleaned up using the pedestrian rotaries and re-cut and marked for rugby. Football pitch lines are greened out, while all the rugby lines are marked with low concentrate white paint, making it easy to remove after games. The staff use transfer wheel line markers and string out for every line. For both rugby and football lines it usually takes about an hour and half to mark out.

I have to say that the pitch was in excellent condition for the time of the year, with no visible wear in either of the goalmouths. This is mainly due to Dan's management of the pitch and his control of the teams' training and warm up requirements. He is very strict about what clubs can and cannot do, following the FA guidelines and policies rigorously. For example, he puts out temporary goals for goalkeeping warm ups and, whilst allowing crosses into the main goalmouths, he disallows direct shooting.

The pitch is mown daily throughout the growing season, using a combination of mowing techniques. This generally centres around the use of pedestrian rotaries - he has both Honda and John Deere mowers - Dennis 36" cylinder cassette mowers and a Toro triple mower.

Occasionally, he will cut the pitch three times on the day of the match, maintaining a height of cut of 24.5mm.

Dan has now got his pitch management to near perfection, which always starts with a thorough renovation in June, usually straight after the last concert - the stadium usually hosts two or three per year. Dan has perfected a regime to ensure he has adequate time to get the pitch back up and running in time for the new season.

Two to three weeks before the concert season, he will gradually reduce the height of cut on the pitch with the aim of reducing the amount of vegetation. For the last remaining matches, that can be as low as 19mm. Ensuring the plant is growing actively, Dan will apply a dose of glyphosate to kill off the grass. It soon dies off, and is ready to be covered over by the pitch protection systems that help spread the weight of the stage and expected spectator foot traffic.

"This year, the stadium hosted Rod Stewart on the 1st of June and JLS on the 12th. As soon as the concerts are over and the stage removed, Hewitts Sportsturf  Contractors come in and renovate the pitch. Basically, the playing surface is scarified with specialist equipment to remove all surface debris, which exposes the Desso fibres. It is then vertidrained to relieve compaction, topdressed with sand and overseeded with MM60 grass seed. The whole renovation process takes less than seven days, with grass germinating within five."

Contractors come in and renovate the pitch. Basically, the playing surface is scarified with specialist equipment to remove all surface debris, which exposes the Desso fibres. It is then vertidrained to relieve compaction, topdressed with sand and overseeded with MM60 grass seed. The whole renovation process takes less than seven days, with grass germinating within five."

"It is then a case of feeding to get the grass growing and starting the process of mowing to help thicken the sward. After nine to twelve days, the pitch will be cut using Honda rotary mowers. From then on, I use my 'feel' to decide what the pitch needs in terms of fertiliser inputs and other relevant concoctions. I'm not frightened to try new products if I think they can make a difference."

Feeding regimes involve some base N P K, along with some additional additives such as seaweed extracts, biomass sugars, fulvic acids/trace elements and iron supplements.

PrimoMaxx is also applied to aid the performance of the sward, helping maintain colour/vigour and develop a good rooting system.

The stadium has a fully automated pop-up watering system in the pitch, plus statics on hoses to ensure even watering. The system is radio controlled, which enables Dan to water while he is out working on the pitch. Water is applied to keep the pitch stable, to benefit the grass and to help improve the speed of the ball during play.

Like most modern sand based pitches, the Liberty has been prone to nematode damage. Over the last few years, Dan, with the help of Dean Gilasbey from Llanelli Scarlet's, has been monitoring the population thresholds of nematodes in their pitches and has subsequently maintained a new regime to control them. "Dean has become a bit of an expert in the life-cycle of nematodes," says Dan, "He has been working closely with Dr Colin Fleming, and has even purchased his own powerful microscope to help identify different types, monitoring their activity through the taking of regular soil samples."

Dan and Dean are both currently trying a new formulation of nematode suppressant which, to date, has been very successful. The combination of good feeding regimes, pitch maintenance and regular doses of this new formulation has reduced nematode populations dramatically, to such a degree they are well below damage thresholds.

Dan's philosophy is to be totally driven in producing a good pitch, which takes a lot of time and dedication. "No two pitches are the same and there is no set agenda," explains Dan. "It is a case of getting to know your pitch and having a sixth sense about its needs and requirements. Feeding regimes are tailored around these requirements - not cutting off too much leaf at certain times and being preventative with certain products. For example, Leaf Spot, at certain times of the year, can be fed out - why knock the whole plant with a fungicide when other options are available?"

By the time we had finished chatting, it was time to get something to eat, we were both staying at the stadium, ready for one of Dan's notorious early starts!

We even had time to go and see Dean Gilasbey at the Scarlet's stadium, some twenty minutes from the Liberty. There was an evening game on with Llanelli Scarlet's playing Cardiff Blues; a big local derby with a play off position at stake.

As soon as we arrived, Dean came to the gates to let us in and we made our way to his office. We got chatting about his war on nematodes, with Dean showing me some active nematodes on soil samples taken that day. At half time we went out on to the pitch to help put some divots back, and then bade our farewells and headed back to the Liberty.

After a quick bite to eat at the Harvester pub next to the stadium, we made our way back to Dan's office for a bit of a guitar session and a few more beers. This was to be my room for the night, while Dan got his head down in another office. We eventually retired around midnight to get some much needed rest, before our early start, set for 3.00am!

Match Day Pitch Preparation

I was awoken by Dan coming into the office and, within ten minutes, we were both out on the pitch. This was quite an eerie experience as the pitch was lit up by one set of floodlights to allow us to see what we were doing. The pitch had received 2.5mm of rain and the air temperature, when we started, was 7°C .

I was awoken by Dan coming into the office and, within ten minutes, we were both out on the pitch. This was quite an eerie experience as the pitch was lit up by one set of floodlights to allow us to see what we were doing. The pitch had received 2.5mm of rain and the air temperature, when we started, was 7°C .

I started rattling off some pictures to capture the moment - I took over 500 pictures over the course of the day! Perhaps in an attempt to make me put down my camera, Dan asked if I would be keen to help mow the pitch and, not wanting to let Dan down (but feeling rather rusty), I agreed to have a go. Dan set up the stripes and I followed. The first few runs were quite testing - the nap on the sward was quite fierce, tugging at the mower - it was a case of putting enough pressure on the mower to keep it straight. Cutting height was set at 22.5mm. Why 22.5? As Dan says, "It's not 22mm, and it's not 23mm!"

Dan uses turning boards to prevent excess damage to the pitch, moving them up and along as they go.

I did offer to stop mowing if Dan thought I was below his standards, but he was happy to let me continue. I felt very proud to be mowing his pitch. It was certainly a first for me - not many people can say they have mown a football pitch at 3.00am in the morning!

I did offer to stop mowing if Dan thought I was below his standards, but he was happy to let me continue. I felt very proud to be mowing his pitch. It was certainly a first for me - not many people can say they have mown a football pitch at 3.00am in the morning!

We had nearly finished the first cut when Dan Kirton appeared at around 5.30am. Dan took over from me and they proceeded to finish the first cut. After a quick break, a re-fuel and a check of the cylinders, both Dans carried out the second cut across the pitch.

They started on the south side and worked their way up the pitch. At various times, Dan K would stop and begin marking, stringing out the lines before using the transfer wheel line marker, marking in two directions. The weather forecast was for some showers during the day, however at 7.30am Dan decided he needed to apply some water, putting on about 2mm. It was a simple task of using the hand held radio and dialling in the allotted time for each pop up to come on. It was quite a sight to see a pitch being watered, marked and mown at the same time.

Once the bands were completed, Dan proceeded to get the Toro Triple and began mowing the perimeter of the pitch.

Once the bands were completed, Dan proceeded to get the Toro Triple and began mowing the perimeter of the pitch.

It was now 10.00am and it was left to Dan K, now with the help of Anthony, to finish marking the pitch. It was then a case of putting the main goals up and setting the nets, placing the portable goals into position and putting the corner flags out.

All the work was completed by 11.00am. Dan likes to give himself plenty of time to chill out and make final preparations ready for the match. There are a few official duties to undertake, such as meeting various officials, taking down some pitch barriers and seeing to other little jobs before the match starts.

It was at this point that the Stadium Manager, Andrew Davies, came across and introduced himself to me. He was keen to  praise his hardworking groundstaff, stating what a great job they had done all season. He said that he and Dan had built up a great working relationship, which was the key to the smooth running of the stadium. He is so confident in Dan's ability that he very rarely gets involved.

praise his hardworking groundstaff, stating what a great job they had done all season. He said that he and Dan had built up a great working relationship, which was the key to the smooth running of the stadium. He is so confident in Dan's ability that he very rarely gets involved.

By this time, many of the stewards were now on site and in position having had their briefings.

Kick off was at 12.45pm, so it was simply a case of waiting for the teams to come out for their warm ups. As soon as they do, both Dans make a point of reminding the coaches of the warm up regulations. In the main, most teams keep to the rules - any that don't, have Dan to answer to!

As soon as the players left the pitch, Dan and his team quickly went back out, removed the portable goals, inspected the pitch and divoted where necessary. The pitch showed very little damage from the warm ups.

With less than ten minutes to go before kick off, Dan decided to apply some more water to the pitch to make it slick and fast and, within minutes, it was watered.

It was now a case of going back to our seats in the stand and enjoying the first half.

At half time, we were back out on the pitch to repair divots. Again, Dan chose to run another cycle of watering to help maintain surface playability.

With the second half under way, Dan briefs his staff that there may be a pitch invasion, so we needed to be prepared and get the posts down as quickly as possible once the game had finished. More goals scored in front of a great, noisy crowd of 17,584, with the final score, 4-0.

As soon as the whistle blew, we were in position, with both sets of goals down and corner flags secured within five minutes. Although some of the crowd did get onto the pitch, they were soon ushered off by the stewards, much to Dan's relief.

Game over, a long rewarding day for all concerned. We made our way back to the office to reflect on the day, while I waited for the crowds to die down before making my four hour drive back home.

I would like to take this opportunity to thank Dan and his dedicated staff for putting up with me; it was another opportunity for me to promote the hard work and sheer effort it takes to produce a playing surface for professional football. It goes without saying that the rewards come when you put the effort in, and Dan and his team have set them selves very high standards. The team, however, are still keen to improve the pitch - having more lighting rigs would definitely help but, at the end of the day, all groundsmen are governed by the resources and budgets available.

selves very high standards. The team, however, are still keen to improve the pitch - having more lighting rigs would definitely help but, at the end of the day, all groundsmen are governed by the resources and budgets available.

Whatever level we find ourselves working; you can achieve immense results with the right attitude, knowledge, dedication and commitment. Dan Duffy and his team have proven this by what they have achieved at the Liberty Stadium. Their pitch must be one of the best around, and I can certainly vouch for it myself. I saw at first hand the level of work put in and the attention to detail Dan adheres to. He and his staff are a true credit to our industry.