Rotary Mower Blades

As part of our regular quest for the perfect aftercut appearance, we diligently sharpen and maintain the blades on our rotary cutting units. We make sure that the blades are sharp and able to provide the cleanest cut possible to continuously chase that perfect aftercut appearance. But are you also aware that there are a couple other areas of the blade that need to be checked to make sure that the blades are structurally sound and also to make sure that there is no other condition with the blade that can make the entire machine require more power to operate and decrease the overall efficiency of the unit.

are a couple other areas of the blade that need to be checked to make sure that the blades are structurally sound and also to make sure that there is no other condition with the blade that can make the entire machine require more power to operate and decrease the overall efficiency of the unit.

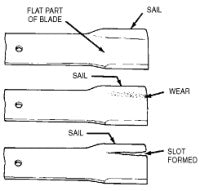

From an overall safety standard, the area of the blade referred to as the sail needs to be inspected. As the cutting unit is operated the sail of the blade generates suction under the deck and helps to stand the grass up so it can be cut efficiently and consistently. The suction caused by the sail not only stands the grass up but will also suck up dirt and sand from the soil as well. These dirt and sand particles will have an abrasive effect on the blade and over time can wear the blade at the base of the sail. If this wear is allowed to proceed to a point where it wears through the blade you can get into a situation where the sail actually separates from the rest of the blade becoming a projectile that may be ejected from under the deck. Anytime a blade is removed for sharpening this area of the blade needs to be thoroughly inspected and replaced if wear is noticed.

Another issue with rotary mower blades is blades that have been bent. When a blade contacts a solid object, the blade can bend, if the blade is bent, the cutting unit will require more power to operate. If the end of the blade tips are bent upward, as the mower cuts grass, each successive pass of the blade will cut the grass at a little lower height then the  previous pass. This multiple cutting of the same grass blade can significantly increase the horsepower requirements and reduce the efficiency of the cutting unit. In the case of multiple blade units this will give a very poor aftercut appearance because of the differing heights.

previous pass. This multiple cutting of the same grass blade can significantly increase the horsepower requirements and reduce the efficiency of the cutting unit. In the case of multiple blade units this will give a very poor aftercut appearance because of the differing heights.

Lastly, when a rotary blade has been bent, the structural integrity of the blade also is suspect. With that being said, it is important to note that if a blade is bent, the blade should never be straightened. If the blade was fatigued when it was bent, it will be even more fatigued when it is straightened.

While we all spend a lot of time making sure that the blades are sharp and cut efficiently, we also need to make sure that there is nothing else wrong with the blade that can impact the overall safety of the machine or the efficiency of the machines operation.

Summary.

When grinding your blade try to keep to the manufacturers original angle and grind only the cutting edge.

Do not grind the bottom of the blade, this will cause a chisel shape and lead to poor quality of cut and increase the horsepower requirement.

After sharpening, balance the blade using a blade-balancing tool, a balanced blade will stay in the horizontal position but an out of balance blade will settle with the heavy side down. If this should be the case then grind a little material from the heavy side, check the balance often it will be quicker in the long run. The consequences of unbalanced blades range (depending on machine type) from premature wear of crank shaft bearings, spindle bearings, hydraulic motors, belts and excessive vibration leading to fatigue cracking of baffles and/or decks.

Refer to the manufacturers torque specification for tightening up the retaining bolt(s) and always check the torque when a blade has hit a solid object.

Do NOT straighten a bent blade instead fit a new one.

Do NOT weld a cracked or broken blade instead fit a new one.

These few notes apply to all rotary mowers whether they are sophisticated multi unit, ride on, all singing, all dancing gang mowers or the lowly walk behind plastic deck hover mower.