The use of permeable materials

The use of permeable backfill over subsurface drains is essential in all sportsfield applications. The function of the backfill is to provide a free draining connection between the upper soil layers and the drains. The material used should be suitably sized permeable backfill. Design should ensure that the permeable backfill extends sufficiently near to the surface to intercept any secondary treatment and to ensure adequate water entry into the drains. Secondary treatments, other than for maintenance should not be specified unless an adequate drainage system with permeable backfill is already in place.

The use of permeable backfill over subsurface drains is essential in all sportsfield applications. The function of the backfill is to provide a free draining connection between the upper soil layers and the drains. The material used should be suitably sized permeable backfill. Design should ensure that the permeable backfill extends sufficiently near to the surface to intercept any secondary treatment and to ensure adequate water entry into the drains. Secondary treatments, other than for maintenance should not be specified unless an adequate drainage system with permeable backfill is already in place.

The design depth from the surface to the permeable backfill may vary but should be at least a minimum depth of 100mm from the playing surface. Care should be taken to ensure that injury does not occur due to gravel or stone backfill material extending to the surface.

The choice of material for topping up permeable (gravel) backfill is extremely important. Advice on the most suitable material should be sought from suppliers, consultants, and contractors.

Selection of permeable backfill materials is of utmost importance. All backfill material placed over drains or in secondary treatments, should be clean, durable and free from dust, lime, and chemical or other pollutants.

Granular Backfill

The backfill material placed over drains should be clean, washed aggregate, shingle or other suitable stone. Good quality artificial material, such as Lytag, may be used in certain applications.

Recycled material may be utilised provided it conforms to the specification below.

The material should have a narrow particle size range. The recommended limits for drains in grass pitches topped with sand are 5mm - 10mm.

Sand Backfill

I t is imperative that the sand or sand/soil mix used is of the correct particle size to prevent migration into the granular backfill. Where this is not the case a blinding layer should be used to prevent any such migration. For example, a fine sand or sand/soil mix used over 5-10mm granular backfill is likely to require a blinding layer of 50mm depth.

t is imperative that the sand or sand/soil mix used is of the correct particle size to prevent migration into the granular backfill. Where this is not the case a blinding layer should be used to prevent any such migration. For example, a fine sand or sand/soil mix used over 5-10mm granular backfill is likely to require a blinding layer of 50mm depth.

For fuller details of sand type selection and use see the accompanying chart.

Note should be taken of what sand is available locally and, if in doubt, advice should be sought on its suitability.

Backfilling with Permeable Fill

Suitable permeable backfill must be placed over the drains to the required depth.

Any loose soil or other material on the pipe should be removed and soil should not be permitted to mix with the fill material. Aggregate or sand hoppers are recommended so as to regulate the depth of the backfill and to minimise spillage and prevent soil ingress.

The backfill must be placed in such a manner as to avoid damage to, or displacement of, the pipes. Backfilling over subsurface drains should normally extend to within 100mm to 150mm or so of the surface as to intercept the topsoil layer. The final 100mm of backfill should be a suitable sand, rootzone, soil or turf, depending on the application. Where slitting, banding or other secondary treatment is specified, the permeable backfill over the subsurface drains must interconnect with that treatment.

Catchwater or French drains, such as those beside all-weather surfaces, should have permeable backfill to the surface. In some cases, the final 50mm may be sand. Care should be taken when backfilling to keep the stone backfill free of soil.

Note: Settlement of the backfill often occurs. Usually it is due to shrinkage of the clay fraction of the soil as a result of the drier soil regime. It can be severe in periods of prolonged drought in the early years.

Once settlement has occurred, remediation measures are limited to topping up. On intensive schemes, general sand or root zone top dressing may be an option but deep settlement will require specific application to individual trench lines by means of specialist equipment. Subsequent maintenance may be required.

Secondary Drainage Treatments

A secondary treatment is regarded here as any treatment placed over a primary piped drainage system so as to improve the drainage response.

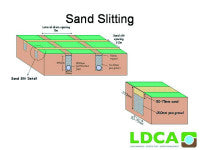

Slit trench drainage refers to narrow trenches from which the soil has been removed, usually 50mm wide and 200-300mm deep, partly backfilled with gravel and topped with sand.

Gravel band drainage refers to bands of gravel, or sand, installed using a trenchless method - i.e. a solid vibrating tine slicing through the soil with the permeable fill being placed simultaneously.

These techniques, along with sand placement/grooving, subsoiling and mole ploughing, increase surface infiltration and improve drainage of the surface and upper layers.

Secondary drainage treatments should only take place over a properly designed and correctly installed primary piped drainage scheme.

Slit Trench Drainage

Slit trench drainage consists of an intensive system of narrow trenches backfilled with permeable materials running approximately at right angles to the drainage. They may be spaced as closely as 500mm apart but spacings of 1-2 metres are more common. Their purpose is to move excess soil water speedily to the piped system.

Specialised trenching machines should be used to cut and backfill the slits. The machines should be fitted with spoil conveyors to load transport leaving the sward clean and uncontaminated.

The trenches or slits are normally filled with a suitable coarse sand or with suitable 5 - 10mm washed gravel topped with sand.

The correct depth of permeable backfill must be maintained at all times and specialist hoppers should be free-running and frequently inspected for blockages.

Spacing of slits, length of run between underdrains, and the depth of the slits depends on the soil type, the sporting activity and the intended intensity of use. Also, the close spacing gives a very rapid drainage response where the piped drains are spaced 5-7m apart; less so where the piped drains are 10m apart. Annual sand top dressings at the rate of 150 tonnes per hectare should be stipulated for the following 2 - 3 years to further enhance this system.

Gravel Band Drainage

Gravel band drainage consists of an intensive matrix of sand or gravel bands running at right angles to the underdrainage. The bands are usually 20mm wide, spaced a maximum 500mm apart, up to 250mm deep and backfilled with 2-4mm gravel or with one of the manufactured products; e.g. Lytag. The installation work is undertaken when soil moisture levels are medium to high to prevent heave. As with slit trench drainage, in the early years soil shrinkage can cause some settlement of the permeable fill in the bands in very dry weather. However, the bands being narrow and more closely spaced, the settlement is usually far less pronounced. Where action needs to be taken an overall sand dressing worked in with a mat usually suffices.

MAINTENANCE

Sand Top Dressing

Following drainage operations, primary or secondary, a suitable sand top dressing is recommended. Care should be taken to spread the sand evenly over the surface. Application should be by means of specialist low ground pressure equipment to prevent damage or compaction and the sand should be worked into the turf to prevent smothering.

Annual sand top dressings at the rate of 120-150 tonnes per hectare should be stipulated for the following 2 - 3 years to further enhance the drainage system.

Further information on Sportsturf Drainage can be downloaded from the LDCA website www.ldca.org and a list of LDCA members can be found by clicking on Members Directory.