What a relief ...

"In our opinion, backlapping should be banned as the carborundum paste is environmentally unsound"

We have read several articles about sharpening reel mowers recently, and very few discuss the bed-knife. In fact, some writers thought that the bed-knife was not considered important enough to mention in its relationship to the quality of cut.

We have read several articles about sharpening reel mowers recently, and very few discuss the bed-knife. In fact, some writers thought that the bed-knife was not considered important enough to mention in its relationship to the quality of cut.

In our experience, the "bed-knife" is the most important part of the cutting process and needs careful attention when sharpening and setting any reel type cutting unit for a fine finish.

While we are on the subject, please allow us to set the story straight on the "relief issue" in relation to the sharpening of reel type grass cutting units, drawing from years of practical experience.

Let's first clarify a few fundamentals regarding relief:

• Most importantly, what is relief?

• What do we mean when referring to a 'ground in relief'?

• How do we actually achieve relief?

• What does it do for the mower?

Relief is the reduction of contact pressure between reel and bed-knife surfaces, offering a "relief" to the engine or mechanism that is powering the reel.

In the turf machinery industry, making the profile of each reel blade thinner, so that there is less metal to metal contact between reel and bed-knife, is usually called relief grinding.

This relief reduces the mechanical effort required to drive the reel when reel and bed-knife are in contact.

It is better to refer to this relief grinding as "blade thinning", it is a much more appropriate description.

The required thickness and angle of blade thinning (or none) varies from one mower manufacturer to another, and you must look at your own supplier's recommended requirements.

It's worth noting, however, that excessive relief angles and relieving to a thin edge will weaken the reel blades, and render them more vulnerable to wear and damage from stones or metal objects such as golf shoe studs or coins.

Here is a short summary of how blade thinning or relief grinding tends to operate in practice.

When you reduce the profile of each reel blade to 25% of its original thickness, by blade thinning from the back edge, we could call this a 75% relief, when there is light contact between the reel and bed-knife blades.

When you reduce the profile of each reel blade to 25% of its original thickness, by blade thinning from the back edge, we could call this a 75% relief, when there is light contact between the reel and bed-knife blades.

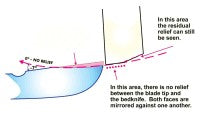

Most golf course equipment technicians will agree that, after running through sand or back-lapping the cutting units a few times, this area (25% in contact) starts to grow, and it's not long before over 50% of the reel blade is in contact across the partially worn bed-knife. So now we have only 50% relief remaining.

If, however, the same reel blade were to operate without any contact with the bed-knife, then you could say that this is 'zero contact' and is, therefore, 100% relief, because the reel is no longer rubbing on the bed-knife.

So, surely, it makes more sense to set all of your cutting units with "zero contact" and have 100% relief all of the time? We do at Celtic Manor and it works well for us, however, the real trick is to keep that zero contact at all times and also to keep a superior quality cut.

Relief has nothing to do with cutting grass. It is all about making the mower work easier when running contact.

We have found that sharpness of the reel has nothing to do with relief whatsoever. Sharpening reels need only take place when the quality of cut deteriorates.

The true answer to relief is to keep a good sharp edge on the bed-knife and never allow the reel and bed-knife to touch - 100% relief.

So how does your reel mower really work?

Is it a Scissor? As a scissor, the cutting unit will be set-up with contact between the reel and the bed-knife.

This is how the mower unit will be set if you backlap at any time during the cutting season, because, once you have back lapped, you will have made the blade surfaces match each other by rubbing them together with a carborundum lapping paste. The blades will then only work as a scissor, which requires reel and bed-knife contact.

The lapping process will not have sharpened the bed-knife's front edge, so you have not improved the quality of cut, you will have just smoothed out the action of the reel blade and bed-knife working in contact, which will show a temporary improvement in cut. Have you noticed that lapping becomes more frequent in order to keep a barely acceptable quality of cut?

With a scissor cut, grass blades are torn off when they are trapped between the reel and bed-knife. As you can easily see with a magnifying glass (or macroscope), the torn edges of cut grass blades look ragged and suffer agronomically from this tearing action. In fact, bearding of grass underneath the bed-knife, or a build up of grass resins on the face edge of reel blades, are visual symptoms of this tearing and bruising action. This is a scissor cut.

A few facts about backlapping

Whenever you see evidence of sand wear grooves on the reel blades, there will always be opposite and matching grooves on the top face of the bed-knife.

After back-lapping, take a magnifying glass and you will be able to see similar, but finer grooves on the reel blades, your bed-knife top face will be the same. No sharpening has taken place, you have only matched the faces of the reel and bed-knife together, the blades will now only cut when set in contact.

You should understand that backlapping paste is just a finer form of sand.

Understand, therefore, that it is absolutely essential to continually relief grind (blade thin) the reel blades, by at least 75% of their thickness, if you are going to continue to backlap and run contact, thereafter setting up as a scissor.

It is the only way this lapped mower will work without major stress to the transmission, reel bearings and power unit.

In our opinion, backlapping should be banned as the carborundum paste is environmentally unsound. In addition, backlapping damages your mowers in several ways including, most notably, it cones reels and can damage reel bearings.

The time spent annually lapping mowers vastly exceeds the time it takes to face the bed-knife, with a facer or file and in-situ spin-grind a reel properly.

Is it a scythe?

When you set a mower as a scythe the reel becomes a gathering device, bringing the grass crop to the bed-knife.

The bed-knife is the scythe's cutting-edge. Correctly sharpened and angled, it allows it to present the grass crop for the reel to pull in against the sharp front cutting edge.

No contact is required between the reel and bed-knife when setting as a scythe, just sharp edges, particularly on the bed-knife. The spiralled helix shape of the reel blades are designed to provide a sideways action when drawing the grass along the bed-knife. The bed-knife has to be sharp at all times.

Scissors will cut, but a scythe cuts cleaner. This is precisely why a surgeon uses a single-blade scalpel (which is drawn through the flesh) instead of scissors.

Scissors will cut, but a scythe cuts cleaner. This is precisely why a surgeon uses a single-blade scalpel (which is drawn through the flesh) instead of scissors.

When setting the mower as a scythe, with zero reel to bed-knife contact, there is no need for a blade thinning a relief, 100% relief is there all the time, so the machine runs easier and with less energy input, less fuel use, lower hydraulic pressures and so on.

When using an easy to set, in-situ type spin grinding method with the ability to set up and sharpen quickly, you can lightly renew the reel's edges as needed, face up the bed-knife and always keep the "no contact" setting in minutes. This is a scything cut.

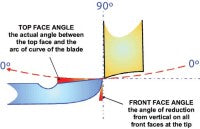

To maintain a scything cut the bed-knife is the most important part. The bed-knife has three functions:

1. Presentation - the front face edge primarily stands the grass up and presents it for the reel, at the right height. It must be sharpened at the correct angles.

2. It is a cutting edge, therefore, the bed-knife must always be sharp.

3. Ejection - the top face angle is for ejecting the grass cuttings from the cutting edge. This angle will vary according to the mower's intended use, but the top face angle is never smaller than the reel diameter. Therefore a 5 inch diameter reel will require a 5 degree top face minimum, then add 2 or more degrees for the grass crop on say a fairway cut. This will vary in different growth conditions.

Bedknives do all of the cutting when you set up a mowing unit like a scythe, the blade must be sharp and have the correct angles on the top face and the front face.

Two thousandths of an inch gap between reel and bed-knife is ideal in Northern Europe, but will need to be reduced by half on some exotic or desert grass species.

It is important to maintain the sharp edge on the front of the bed-knife, with a facer or a good file, in order to cut cleanly without bruising the grass. This will also enhance the definition of stripes on the green, thereby improving the after cut appearance and keeping the pace consistent on greens all day during competitive play.

Experiences at Celtic Manor

We have eight Toro 5410 fairway mowers, five were purchased in 2007 and three in 2008. We do not backlap in favour of grinding because it's quicker using our spin grinders.

The 2007 machines have been sharpened twice, the first time to see how long it took two men to grind five machines during the average work period in peak season (7 hours). Using a calculator it's easy to see that:

The 2007 machines have been sharpened twice, the first time to see how long it took two men to grind five machines during the average work period in peak season (7 hours). Using a calculator it's easy to see that:

7 hours = 420 minutes divided by 25 cutting units = 16.8 minutes per unit.

The time started from driving in the first machine to driving out the last one.

This included removing the bed bar, grinding the bed-knife on the top edge and front face, adjusting the height of cut post grinding, and greasing each unit before refitting it to the machine.

The technicians carry out all bed-knife to reel adjustments, we set-up all of our units with no contact at all and the quality of cut is first class.

During tournaments, we give every pedestrian greens mower a very quick spin each time they are used, this takes around five minutes per machine and includes a couple of passes with our Rapid Facer to 'freshen' the bed-knife front face, and make fine adjustments to the height of cut.

This is a 'belt and braces' measure, purely for tournaments, because of the limited time for course set-up before the first tee-offs, the mowers must go out in "perfect" condition.

Some figures for you to consider;

From independent field trials we know that, when running a five unit fairway mower set with zero contact, the hydraulic pressure will be around 900lbs, causing minimum mechanical stress to the machine.

Running the same mower set with light contact, but with reels easily turning, the hydraulic pressure will increase to 1800lbs. Because the reel and bed-knife contact begins to act like a brake, as reels get hotter and begin to expand slightly, more heat or heavy contact will increase the braking effect still further.

Due to this braking effect of running reels with light contact, the mower's fuel consumption will increase by 25 to 30%, the transmission oil and engine oil temperatures will be raised, producing extra stress on hydraulic hoses, motor seals and reel bearings, the risk of oil leaks will increase, reel and bed-knife wear will be much higher and quality of cut will deteriorate rapidly.

Professional hydraulic mowers have built in safety relief systems (similar to 3 point tractor lifts), which will release pressure when the hydraulic system reaches about 3,000lbs. This means that any heavy reel and bed-knife contact will begin to open the safety valves and risk causing the hydraulic safety system to bleed off pressure and, so, reduce the efficiency of the mowing unit or stall the cutting units entirely.

Remember that the way you set-up, maintain and use your equipment will change the performance and useful life of your mowing machines. It will also effect your manufacturer's reputation and warranties.

Reducing the wear and tear on your machinery, and always setting your mowers with a perfect zero contact cut, will enhance your own reputation and, by providing consistent, high quality playing surfaces, you will ensure that your members and paying customers want to return again and again.

Do your own 'zero contact' cutting trial today. It may change your life.