Amazone Groundcare to announce new multi-purpose spreaders at the NEC

The Amazone E+S single-disc spreader has always been at the forefront when it comes to flexibility. The steep-walled hopper ensures that all types of spreading material will flow making the spreaders ideal, not just for winter salt application, but also giving them the ability to spread both granular fertiliser as well as sand and top-dressing materials onto sports pitches and golf courses. The wide, even spread patterns make covering large areas easy and yet with the utmost of precision. This flexibility makes them usable year-round, thus spreading the cost of investment.

The brand-new E+S 01 series is fresh from the ground up with its newly-designed hopper featuring a stainless steel tip - along with bottom assembly and spreading system also made from stainless steel - a winner all round for maximum longevity and easy maintenance. New bolt-on hopper extensions increase the capacity of the 300 litre base unit to a maximum of 590 litres and, for bigger tractors, the E+S 751 can be extended up to 1,110 litres.

For keeping the hopper contents dry, the new hoppers have the option of either a stretch sheet or a new swivel hopper cover that features a see-through panel to monitor the hopper contents. A protective sieve is fitted as standard and any spreading material is kept off the tractor by use of the new rubber splash guard. Both the road lights and the optional work lights are LED panels with the work lights shining red for better visibility when spreading on icy roads and at night.

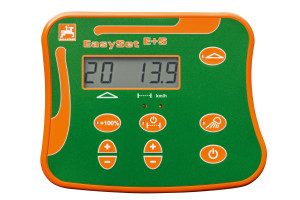

All the controls for the new spreaders are located at the rear of the hopper for easy access and feature asymmetrical spreading capability and the spreading unit has been brought, bang up to date, with the use of intelligent electronic controls for optimum coverage and ease of operation.. This means, for example, that pavements can be spread from the road when travelling in either direction.

The new E+S 01 series, designated the E+S Hydro, features a hydraulically-driven spreading disc that is adjusted in speed from the cab to give different spreading widths. This means that no spread width limiting skirt is required to control the spread pattern which helps avoid the creation of any salt dust which can hamper spread and also could cause corrosion issues for the spreading tractor. The aperture on/off is controlled electrically.

The application rate can be adjusted up or down from the tractor seat if necessary to suit the conditions on the road. Additionally, the disc reduces down to 80 rpm when the carrying vehicle comes to a stop preventing any unnecessary grinding of the spreading material.

The new spreaders can be found on Stand H055 at IOG Saltex, NEC Birmingham starting on November 1st