For FOCs Sake!

To begin this article, I would like to quickly review the theory and fundamentals of the cylinder mowing process. I may be teaching many of you to suck eggs but, understanding the principles of mowing fine turf, is a good starting place.

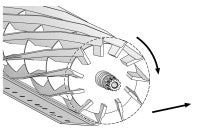

A cylinder mower cuts grass with a scissors-like shearing action between the rotating cylinder blade and the stationary bottom blade (also known as a bedknife). The cylinder has a number of helical knife-like blades, evenly spaced and maintained at the same cutting angle on round support members called spiders, webs or collars.

A cylinder mower cuts grass with a scissors-like shearing action between the rotating cylinder blade and the stationary bottom blade (also known as a bedknife). The cylinder has a number of helical knife-like blades, evenly spaced and maintained at the same cutting angle on round support members called spiders, webs or collars.

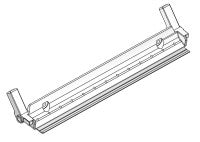

The cylinder shaft is driven by drive gears, belts, or motors. Below the cylinder is a flat, stationary bottom blade mounted rigidly on a solid backing plate. The bottom blade holds the grass erect and, as the rapidly rotating cylinder blades pass over the bottom blade, they cut the tops off the grass blades.

This cutting action is referred to as "shearing," "clipping," or "scything" by various mowing and sharpening equipment manufacturers.

Quality of Cut

Cylinder mowers have always provided the most effective means of maintaining well groomed lawns, parks, athletic fields, and golf courses. Mowing to a schedule with correctly adjusted and sharpened cylinder units is the most important factor in maintaining healthy, well-groomed turf.

Quality of cut refers to how well the individual grass blades are cut. A properly adjusted and sharpened cylinder mower cuts grass cleanly without tearing, shredding or bruising the grass blades. In addition to the sharpness of the blades, the adjustment of the cylinder blades to the bottom blade and the gap (clearance) between the cylinder blades and bottom blade are crucial to the quality of cut.

The bottom blade must be flat and true where it meets the bottom blade backing, with no distortion or gaps

Good Quality of Cut -

Grass, cut with sharp blades and properly adjusted cutting units, has good colour, rapid growth recovery, and a sharp, clean, uniform appearance.

Poor Quality of Cut -

Grass, cut with dull blades or improperly adjusted cutting units, has poor colour, slow growth recovery, and a ragged appearance. This increases drag, resulting in a slower playing surface. Shredded and torn grass blades also tend to require more water and fertiliser and, therefore, cost more to maintain.

Frequency of Cut -

Having looked at the theory and fundamentals of mowing, now let's take a closer look at Frequency of Cut (also sometimes expressed as either Cuts per Metre or Clip Rate) and the consequences of correct and incorrect clip rates.

Frequency of Cut: FOC (expressed as cuts per metre or clip rate) -

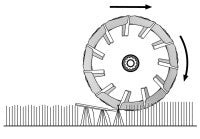

Frequency of cut is the rate at which the cylinder blades cross the bottom blade. In the US, this is quoted as the clip rate, and is expressed as either a decimal of an inch (0.15"/mph), or in millimetres (3.81mm/km/h). To determine the actual clip rate, simply multiply the rate by the speed.

In Europe, FOC is often expressed as cuts per metre. Here, a metre (1000mm) is divided by the clip rate, giving the number of cuts per metre. This, typically, shows the number of cuts per metre at the highest forward speed, therefore the lowest standard of finish likely to be achieved. This measurement is much easier to visualise than clip.

Clip Rate: 0.15" clip at 6 mph = 0.9"

Cuts per metre: 22mm per cut at 9km/h (6mph) = 45 cuts per metre

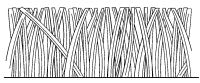

The cutting action of a cylinder mower results in cut grass that has small waves in it. At higher cutting frequencies, these are too fine to see. They can, however, be seen on units with lower frequencies, (meaning larger gaps between each successive cut).

The cutting action of a cylinder mower results in cut grass that has small waves in it. At higher cutting frequencies, these are too fine to see. They can, however, be seen on units with lower frequencies, (meaning larger gaps between each successive cut).

The FOC can be described as the distance between the valleys of two successive waves. FOC is determined by the number of blades per cylinder, the cylinder speed (RPM) and the forward speed of the mower.

As the mower travels forward, the bottom blade pushes against the grass in front of it. At the same time, the cylinder blade is gathering grass as it moves toward the bottom blade. The opposing forces gather the grass blades together at the shear point, and the result is a singular wave-like profile on the cut grass.

As the mower continues to move forward, the cutting process continues for each successive cylinder blade as it passes over the bottom blade.

A cylinder unit is properly matched to the application when the FOC is approximately equal to the height of cut. The lower the height of cut, the more blades a cylinder will contain to match the correct FOC.

Frequency of Cut Too High

When a cutting unit is put into an application with an FOC greater than the height of cut, the waves that were invisible to the eye with the correct FOC are now visible. This is known as 'ribbing' in Europe or 'marcelling' in the US.

The most common cause of ribbing or marcelling is driving the mower too fast over an area. This leaves a very noticeable short, choppy wave pattern.

Frequency of Clip and Ball Speed

In the golf environment, when the FOC is equal to or less than the height of cut, the wave-like profile of the grass is minimal and the smoothness of the turf  surface allows faster ball speed.

surface allows faster ball speed.

When the FOC is greater than the height of cut, the wave pattern is larger and the surface is not as smooth, so ball speed is slower. A greater distance between clips is also more susceptible to stragglers than a shorter distance between clips. Stragglers further slow ball speed.

Cylinder configurations vary by diameter, cutting width, and the number of blades. The cylinder diameter and cutting width are usually fixed by the design of the cutting unit. A particular cutting unit, however, may offer cylinder options for the number of cylinder blades desired. The number of blades is one of the factors in determining the FOC.

Finally, let's have a look at some theoretical applications

Application

As we can now appreciate, the number of blades in the cylinder, rotational speed of the cylinder, and mower ground speed determine FOC. The lower the FOC, the smoother the cut.

In application, a 5-blade cylinder turning at 1200 rpm would provide enough clip rate for roughs, while an 11-blade cylinder turning at 2000 rpm might be required for greens on a golf course.

When a customer is considering the correct cylinder for the application, it is important to check the manufacturer's stated FOC. A good rule of thumb to use is that the FOC should be within 20% of the height of cut.

Example 1

Green Acres Golf Course wants to purchase a trim mower. The unit can be purchased with 5, 7 or 10-bladed cutting units. Which cutting unit should the customer purchase? The first question to ask the customer is; What is your preferred height of cut?

The customer replies that it will be 19mm.

The customer replies that it will be 19mm.

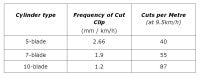

Now, look at the manufacturer's specifications on FOC. In this example it states:

It is important to note that manufacturers are not consistent in stating their FOC in relation to mowing speed. Some manufacturers give the figure at a stated mowing speed, while others do not. It is therefore necessary to return to the specification sheet and confirm what the mow speed is.

Others may quote the cuts per metre (usually at the full mowing speed), as this is how most machines are actually used.

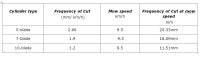

In this example, the specification sheet (see table below) stated that the unit can mow up to 9.5km/h (6mph). By multiplying the FOC by the forward speed, we can find the actual FOC for any given speed.

Since the desired height of cut is 19mm, we need to have the FOC within 20% of this number. The 7-bladed cylinder has a near perfect FOC of 18.09mm, which satisfies the within 20% rule.

The FOC for the 10-bladed cylinder is out of the recommended 20% margin, and the additional blades will cause more air turbulence. There will be more chance that the 10-bladed cylinder will fan the grass, causing it to not stand up for a clean cut.

Example 2

Hometown School wants to buy the same type of mower to use on its sports pitches. The customer's height of cut will be 30mm. The specification literature states the height of cut range for this mower is 12-47mm.

Hometown School wants to buy the same type of mower to use on its sports pitches. The customer's height of cut will be 30mm. The specification literature states the height of cut range for this mower is 12-47mm.

Our numbers showed us that the best cylinder to use for this application would be the 5-bladed cutting unit. The FOC for the 5-blade is 25.33mm at the 9.5km/h mow speed, again, this is a good match for the 30mm height of cut.

Calculating Frequency of Cut

Example: Trim mower with 9.5km/h (6mph) mowing speed, cylinders turning at 1,250rpm, and a choice of 5, 7 or 11-blade cylinders.

Speed: 1km/h = 1,000 metres/hour / 60 = 16.667 metres/min.

16.667 metres/min X 1,000 = 16,666.67mm/min @ 1km/h (This is a constant).

So, 16,666.67mm/min x 9.5(km/h) = 158,330mm/min.

5-blade x 1250 rpm = 6,250 cuts/min.

158,330mm/min / 6,250 cuts = 25.33mm.

1,000mm / 25.33 = 39.47 cuts per metre.

25.33 / 9.5km/h = 2.66mm/km/h clip.

7-blade x 1250rpm = 8,750 cuts/min.

158,330mm/min / 8,750 cuts =18.09mm.

1,000mm / 18.09 = 55.23 cuts per metre.

18.09 / 9.5km/h = 1.9mm/km/h clip.

11-blade x 1250rpm = 13,750 cuts/min.

158,330mm/min / 13,750 cuts = 11.51mm.

1,000mm / 11.51 = 86.88 cuts per metre.

11.51 / 9.5km/k = 1.2mm/km/h clip.

In all the above calculations, the cylinder speed and number of knives give the cuts per minute. Then, calculating the forward speed in mm/minute, allows a simple division to arrive at a clip rate in millimetres. Dividing this into a metre gives the easy to visualise measurement in cuts per metre.

Although this looks relatively complex, once you have done a couple of calculations, you soon get the hang of it. However, I hope the most valuable take-away from this article has been to explain the importance of frequency of cut and how it affects consistent ball speed.

A lower frequency of cut produces a smoother surface and better ball roll. If you can add to that consistency of cut, it is possible to achieve consistency across all greens.

Jacobsen Eclipse Greens Mowers

In this article we have discussed the importance of frequency of cut at some length. The latest development in mowing technology has been the ability to change the FOC, and then maintain it at a fixed rate, regardless of the forward speed of the machine.

In this article we have discussed the importance of frequency of cut at some length. The latest development in mowing technology has been the ability to change the FOC, and then maintain it at a fixed rate, regardless of the forward speed of the machine.

This has been achieved by using electric motors for both cylinders and transmission, and linking them via a controller. The controller then adjusts the cylinder speed to match the forward speed of the machine.