Looking deeper into Cricket Topdressings

Looking deeper into Cricket topdressings.

By Alan Lewis - NDT. F.inst.G Technical Director Total Turf Solutions

Topdressing has become an automatic operation with the autumn renovation of a cricket square, but with changes in scarification over the last few years, is it time we looked in more detail at the process of top dressing, and more importantly, the materials used.

The reasons for topdressing are well known: improve surface levels, soil strength and to help with germination and soil exchange etc. However, over 90% of the profiles I assess are layered in some form or another, and in most cases this is caused by top dressing. When a surface has no more that two layers, my recommendation is to use holes left by the aeration process, to get top dressing down into the profile and help improve root growth and bind the layers together.

It is time to consider topdressing as two operations? Firstly for surface work, levels and germination and secondly for profile dressing to assist in binding layers together.

When applying top dressing on cricket squares, it is vital that a straight edge is used, not a brush or drag mat. These will only follow existing levels. A straight edge will remove loose material from the high spots and deposit them in the low areas, creating a level surface.

There are many different aspects of the materials used for topdressing, however, let us have a look at some basic points: -

1. Don't change topdressing material unless you know it is compatible with the existing loam, paying attention to clay content, type and shrinkage rates. A simple 'Motty' test will do this.

2. Keep away from high silt contents. Silt does not bind together.

3. Check organic content. This should be below 5%. Hours are spent scarifying to remove organic matter from the surface. If a poor quality loam with a high organic content is used, organic matter could be put back into the surface by the bag load!

4. Ask for a soil analysis each time. This information is required for your COSSH records.

5. Do not dress too heavy. Six bags is an average dress per pitch. It should never be more than ten per pitch as it will not bind with the existing surface, and there is a risk of the top breaking up.

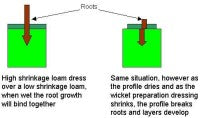

The percentage of clay content in cricket loam is very important. The type and shrinkage rates will effect the binding strength and pace of the pitch. There are different type of clays used for cricket topdressing, the difference being their structure. This structure makes them shrink and swell at different rates. So how does this effect a cricket pitch?

Some loams tested shrink up to 24%. (That means nearly a quarter of their volume). Others shrink as little as 10-11%. The effect of dressing with a high shrinkage loam above a low shrinkage loam would be broken roots as the loam dries out, and hence the layering process begins.

The clay content is also important, however clay content should not be increased any more than 2% - 4% at a time. It is also important to remember that aeration should be increased prior to changing topdressing. Solid tines should be used to ameliorate the loam into the profile.

On the better squares around the country, that do not suffer a layering problem, dressing is used for surface levelling and seed germination. To remove subjective assessments, have your square profile evaluated in advance of any renovation work.

Total Turf Solutions Ltd

PO BOX 250

Northampton

NN5 5WZ

Telephone: +44 (0) 1604 750555