Go Dutch with quality not cost

Thanks to Campey Turfcare, members of the press were invited on a two-day trip to Holland visiting the company premises and machinery of both Imants and Vredo. These two long established companies, with feet in both the agricultural and amenity sports sectors, produce high quality machinery for aeration and seeding respectively.

The two comparatively sized companies put their emphasis on building sustainable equipment that stands the test of time in the field.

IMANTS

The founder of Imants was the local village blacksmith in Reusel, Holland who even back in 1885 had started making hand tools for the farmers and local people. Horse-drawn ploughs soon followed, which because of their high quality, quickly gained the village blacksmith an excellent reputation. The mechanization of agriculture developed in leaps and bounds.

The tractor plough was introduced soon after the First World War. Strangely enough, Landbouwmachinefabriek imants B.V., as it was already known in those days, didn't develop its own tractor plough, but manufactured Imants parts for other plough manufacturers. It wasn't until the 1960"s that it finally developed its own product. It was a spading machine that was built at the request of a local gardener in Reusel, who wanted to dig stable manure into the soil in his greenhouse. After the invention of the driven rotary tiller, which could break up the dug soil and make it ready for sowing, the sales of spading machines really took off.

In the 1990s Felix Peter's (Left) bought the Imants company from the retiring owner, having worked for the company previously. He and his team have continued to develop and build machinery for the agricultural and sportsturf markets. In more recent years two machines in particular have helped to improve the way that aeration can take place in the soil. Imants have continued to develop their Shockwave range, where the machines can follow greens and undulating ground closely, decompacting the soil with little disturbance. The Rotoknife system compliments the Shockwave and offers a range of depths to slit too. The Rotoknife is described by Imants as " the fastest and best aerator in the world,"

In the 1990s Felix Peter's (Left) bought the Imants company from the retiring owner, having worked for the company previously. He and his team have continued to develop and build machinery for the agricultural and sportsturf markets. In more recent years two machines in particular have helped to improve the way that aeration can take place in the soil. Imants have continued to develop their Shockwave range, where the machines can follow greens and undulating ground closely, decompacting the soil with little disturbance. The Rotoknife system compliments the Shockwave and offers a range of depths to slit too. The Rotoknife is described by Imants as " the fastest and best aerator in the world,"

All Imants machines use hardened special quality steels that are now sculptured in the factory using space age high - pressure water cutters. Without the use of any heat process the temper and hardness of the metal is not adversely affected.

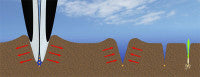

Soil compaction is now recognised as a major problem for all sports turf facilities throughout the world. Compaction is THE prime cause of poor root development, and the under utilisation of air, water and key nutrients, so essential for healthy plant growth and durable sports turf surfaces.

When it comes to rotary decompactors Imants has more experience than any other company in the world. They should have - they invented them! That's why the Imants Shockwave is one of the most reliable decompactors available - anywhere.

This range of machines is totally proven in all conditions for absolute reliability. Toughness that the customer, can depend on day in, day out, year after year.

The machines offer consistent decompaction to full working depth and width of the machine including the particularly critical rootzone area. Incredibly low running costs and ease of maintenance make the Shockwave efficient on your budget.

All moving parts are fully and effectively guarded for operator and public safety. Shear bolts protect all blades and the gearbox from breakage.

Whatever the sports turf surface, be it golf greens to fairways, outfields, racecourses and winter sports pitches you can expect excellent decompaction with virtually zero surface disturbance and disruption to play.

Specifics:

Full instantly adjustable depth control on all models. (Hydraulic depth control standard on 1.6/2.2/2.5metre formats)

• No disruption to play and virtually zero surface disturbance.

• Extremely low maintenance - only four grease points (3 on 1.5m model).

• Vastly improves drainage, root development, drought resistance plus the availability and uptake of nutrients.

• Available in 1.5/1.6/2.1/ 2.2/2.5 metre formats for all situations.

• Working depth down to 550 mm.

• All models now fitted with rear smooth roller as standard.

• Fully protected with shear bolts for maximum safety.

The Rotoknife can be used in conjunction with the aeration program of the Shockwave to: -

The Rotoknife can be used in conjunction with the aeration program of the Shockwave to: -

Help destroy Thatch

Remove Black Layer

Improve Drainage

Break up Pans and Hard Areas

Reduce Algae and Surface Slime

The Rotoknife gives the operator a series of different sized discs that aerate down to 7" in easily adjustable 1" stages. The machine can be tractor mounted, trailed or operated by a utility vehicle with external hydraulics.

It is not necessary to remove thatch as it can be simply broken down where it lies. By constantly slitting with the RotoKnife the integrity of the thatch is compromised, allowing air and water to pass through. At the same time, the slitting disc inoculates the thatch layer with a smear of soil from the lower levels. This soil contains the basic ingredients for the organic destruction of the thatch. Therefore, constant regular slitting with discs, will completely breakdown thatch without any need for removal, providing the basic drainage needs of the soil is satisfactory.

VREDO

The build quality of the Vredo equipment is of similarly high standards, where the company ethos is to provide the right equipment and worry about the cost later. Their range of different size disc seeders put a very accurate rate of seed directly into the ground, ensuring the highest levels of germination.

Their seeders are so well calibrated that they will even put fine bent grass seeds down into a green, slicing through any thatch to within a tolerance of a gram per square metre. With the cost savings on grass seed apparent, the fact that many of their seeders have needed no replacement parts in 25 years makes these high spec. machines extremely cost effective over time.

Operating principle

V-shaped cutter discs make a sharp V-shaped slit. This protects the critical texture of the turf and leaves the microbiological life within undisturbed. The depth of the slit can be adjusted within a range from 0.5 cm to 2.5 cm. A precisely adjustable amount of seed is placed in the bottom of the slit.

depth of the slit can be adjusted within a range from 0.5 cm to 2.5 cm. A precisely adjustable amount of seed is placed in the bottom of the slit.

A heavy roller presses down to cover the slit so that the seeds have the best possible chance of germinating. Experience has shown that 90-95% of the seeds actually sprout and grow.

The growth of the seed and the strength of the turf restrict the growth of weeds. The result is a superb grass cover, suitable for all sports or amenity applications.

Introduced in 2005 after extensive testing, the COMPACT series features an

Introduced in 2005 after extensive testing, the COMPACT series features an

innovated seed-dispensing facility, new synthetic seed containers and newly

designed cam wheels.

This has made the VREDO overseeder more compact. The roller has a smaller diameter and is mounted closer to the sowing elements, and this has also helped to achieve its compact design. The smaller diame ter has resulted in a greater penetrating force with a relatively low weight.

ter has resulted in a greater penetrating force with a relatively low weight.

The COMPACT series reseeder is particularly suited for use behind a compact

tractor. The machines own weight is low, and it is coupled closely behind the

tractor.

The operating widths are 1.00 m, 1.40 m, 1.80 m and 2.20 m.

The sowing distance is the same for all models: only 7.5 cm.

The SPORT series was developed specifically for sports fields and golf courses, they feature a double set of discs and sowing tubes. This has helped to achieve an

extremely high sowing density and sowing distances of only 3.5 cm or 5 cm.

The possibility of high-density sowing with a small tractor is very efficient on high quality turf. The operating widths are 1.30 m, 2.00 m and 2.50 m.

The possibility of high-density sowing with a small tractor is very efficient on high quality turf. The operating widths are 1.30 m, 2.00 m and 2.50 m.

On all Vredo models the important thing to remember is that the seed is enclosed in the slit and good soil/seed contact means excellent germination rates.

For more information and sales please contact Campey Turfcare on

01260 224568 or e-mail info@campeyturfcare.com or visit their website

www.campeyturfcare.com